Over 25 years mechanical & electrical expertise

Delivering increased profitability through design and innovation

The Wet Sparky, your local electricians, aim to provide customers with cost effective solutions and years of industry gained experience. Our vision is to fully understand customer needs and exceed their expectations, delivering increased profitability through design and innovation.

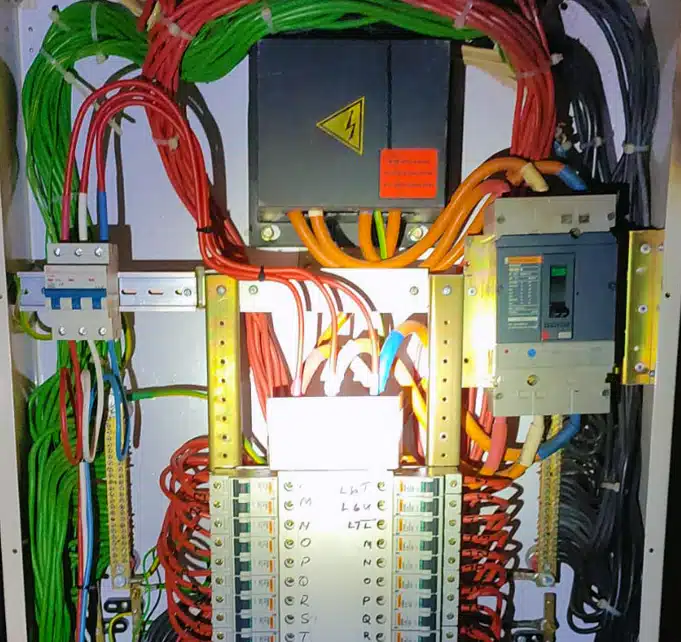

Industrial Services

Keeping your plant running and production flowing is our number one priority. Our team understand that fast fault finding and pinpoint problem solving is key.

Commercial Services

Design and modernization have a huge impact on corporate businesses. First impressions last. We can help you achieve or expand this image…

Residential Services

Upgrade or repair. Install or maintain. From sewage pumps to kitchen renovations. We offer a wide range of Home maintenance services.

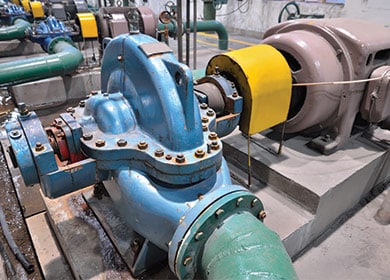

Mechanical Engineering

Full Electrical /Mechanical Site Survey

Prevention costs less than Reaction. Understanding what you have and how it works can reduce downtime. Thermal Audits, Electrical component checks, and plant Condition Monitoring

Our highly trained Thermal imaging analysis team and condition monitoring experts is focused on finding fires before they happen. Friction and loose electrical connections create heat and improper airflow prevent much needed cooling. All these factors can be monitored, maintained and repaired before resulting in major damage to expensive equipment, through a condition monitor program and scheduled preventative maintenance or PM system.

Thermal Imaging

Find Hot Connections

Identify Fire Hazards