Description

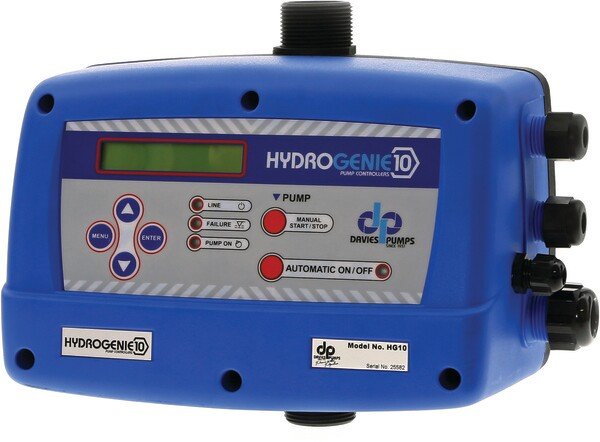

The Davies Pumps Hydrogenie HG10 is a simple and robust inline variable speed inverter pump controller to control and protect pump with three phase power supply.

Simple installation and set up means it can be easily fitted to most pump systems with inverter to vary the speed of the pump motor, maintain a constant set pressure and provide efficiency savings. 1 1/4″ ports for high flow applications up to 15m3/hour.

They can also be set up as a pair with direct communication to control pumps where dual pumps are required for high peak demands, it will also alternate starts and protect motors.

Technical details:

- Frequency inverter type controller

- Output 9A 400V 3Ph

- Max pressure: 16Bar

- Operating pressure range: 0.5 to 12Bar

- Operating temperature range: 0 to +40°C

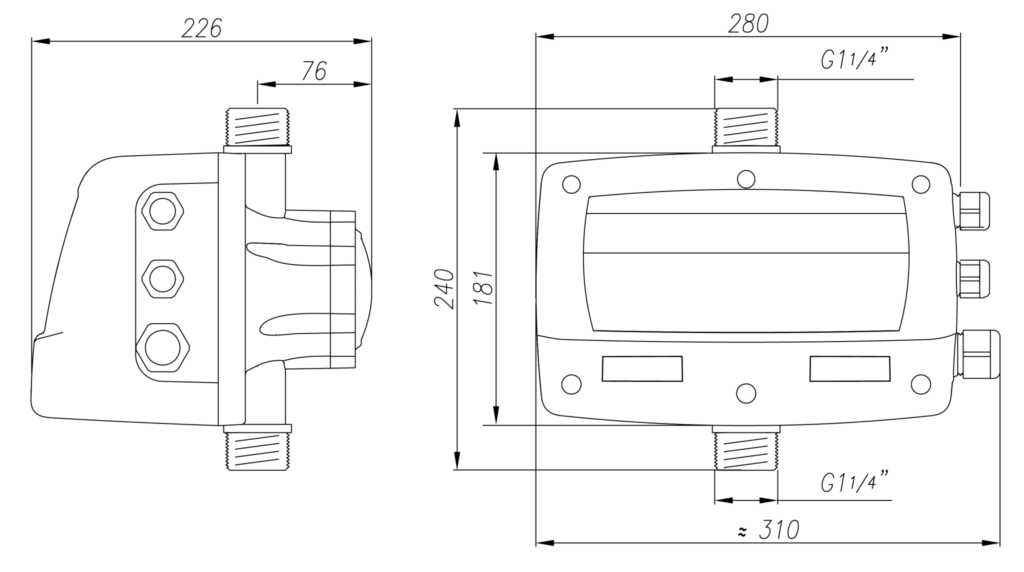

- Connection Thread: 1 ¼” male

- Protection: IP55

- Electronic over current protection

- Run Dry protection

- Over/Under voltage protection

Additional features:

- Digital display: Shows instantaneous motor current, system pressure, set pressure, flow sensor position during normal operation.

- Dry run restart: Following a dry run event the controller will attempt a restart 5min after and every 30min for 24hours if the problem persists.

- Over Current: In the event the current rises above the set point the controller will turn off the pump and attempt a restart 4 times, if after the 4th attempt the current is still above set point the controller will remain off.

- Under Voltage protection- In the event of low voltage the controller stops the pump and remains off until the voltage increase

- Over voltage protection- In the event of high voltage the controller stops the pump and remains off until the voltage decreases

- Ice/Frost protection – In the event the temperature in the controller drops below 5°C the pump will run periodically to prevent the water freezing.

- Alarm register: All alarm events are recorded including Short circuits, Over current, Over temp, Dry run

- Operation register: Records Pump run hours, Number of cycles (start and stop) and Number of connections to the power supply.

- Dual pump control: Two HG8 controllers can be configured to work in parallel and auto-alternate.